Our Manufacturing Process -

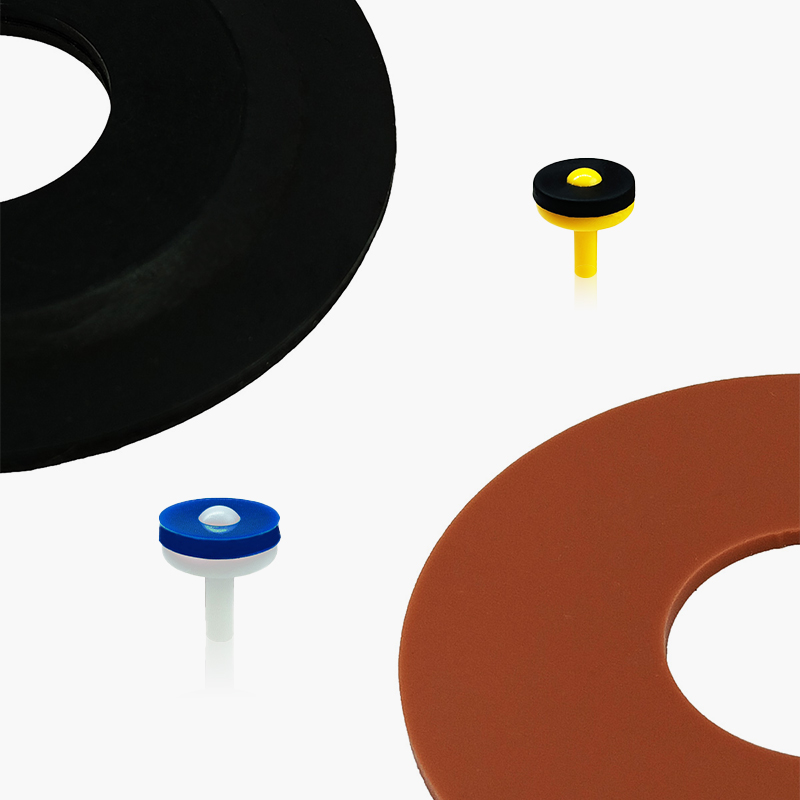

Compression moulding

Compression moulding is one of the oldest manufacturing techniques for rubber moulding. The process parameters include moulding time, temperature, and pressure. Usually, a 300-400 ton clamp pressure is used. The typical mould is shaped like a clam shell with the bottom being the mould cavity.

Our Manufacturing Process -

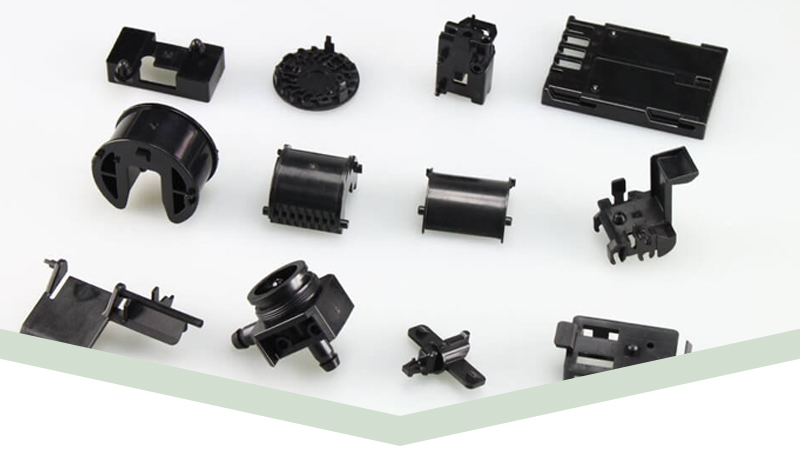

Injection moulding

Injection moulding is a method to obtain moulded products by injecting plastic materials molten by heat into a mould, and then cooling and solidifying them.

- OEM Products & Services -

OEM Product Solutions

Tailored to Your Needs

At TPR Industries Sdn Bhd, we also specialise in providing high-quality, tailored OEM products that meet the unique requirements of your business. From design to production, our team works closely with you to transform your ideas into market-ready products, ensuring both precision and efficiency throughout the process.

Our OEM Product Offerings

Custom OEM Manufacturing

Full OEM Production Process

At TPR Industries, we handle the entire OEM product development process, including design, prototyping, and full-scale production. With our advanced technology and expert team, we ensure each product is manufactured with precision and adheres to international standards.

- Our Features -

Why Choose Us for OEM Products

Advanced Facilities

Our state-of-the-art production facilities enable high-volume manufacturing with consistent quality.

Long-Term Partnerships

We prioritise building strong, long-lasting relationships with our clients, offering ongoing support and collaboration.